Robotic Coping Machine Hs Code

Dragon�s front position gate and chuck is easily adjustable, making the load and setup between different shapes and sized materials a breeze.

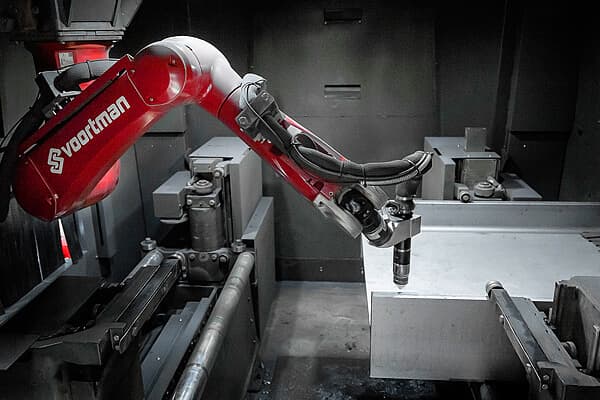

The Voortman V808 robotic thermal cutting machine is equipped with the new faster and more accurate versatile Panasonic TL-1800G3 coping robot. The torch nozzle of the robot is fitted with a measuring sensor to measure the exact profile dimensions. During the cutting process the difference between actual and theoretical dimensions are automatically compensated in the machine parameters to ensure the most accurate product possible. To speed up the process even more, the coping robot only measuring the sides of the profile that will actually be processed.